Dolph’s® offers a wide range of two-component potting resins. These products are specially designed to meet the most demanding conditions of the electrical insulation and electronic protection markets.

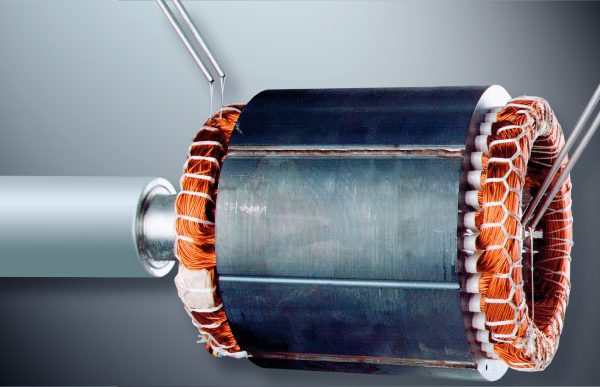

Epoxy systems are based on two-component resins that are mixed in different proportions and cured either at room or high temperature. Different mechanical, electrical and chemical resistance properties can be delivered according to customer specifications. High thermal resistance Class H (180°C) with excellent crack resistance to high temperature variation is a must in the growing electric drive market. These resins are an outstanding solution for any traction application that is subject to harsh environments.

The main advantages of Dolph’s® epoxy are:

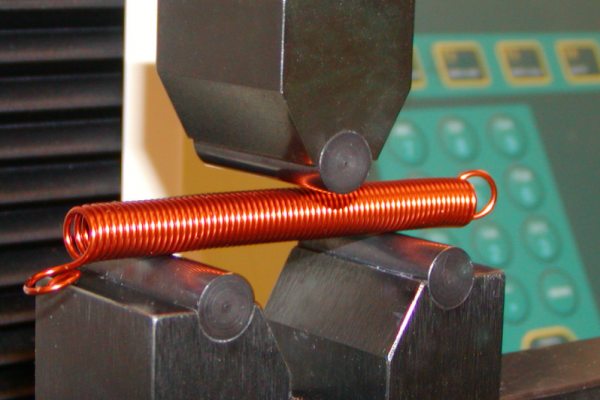

Polyurethane systems improve overall productivity. Potting and casting can be quickly achieved thanks to fast hardening at room temperature. This is a noticeable advantage over traditional materials such as silicones and epoxies. A variety of resin formulations can be blended with several hardeners to produce many different grades, each having selected properties that match processing requirements and adequate characteristics for finished products.

Our polyurethane resins are used for potting, encapsulation and casting of electrical and electronic components. These tailored solutions optimize mechanical and thermal characteristics as well as clients’ processes.

The main advantages of Dolph’s® potting compounds are:

Dolph’s® specialized high-performance product range offers basic handling properties comparable to polyurethane with many other advantages. These include elastomer behavior, outstanding adhesion and flexibility even at very low temperature, and extremely high moisture resistance. These materials are cost-effective substitutes for silicone elastomers, especially in applications requiring high thermal resistance.

Welcome to Europe’s leading center of expertise for high-voltage insulation for rotating machinery. Our knowledge of electrical insulation is based on over 100 years of experience. Discover more about us: