Dolph’s® offers a wide range of impregnation resins. These products are, specially designed to fulfill the most demanding conditions of the electrical insulation and electronic protection markets. Dolph’s products are available for all common processes:

– VPI – Vacuum Pressure Impregnation

– Trickling and Dip-Roll

– Dipping and Hot-Dipping

Solvent-free resins have been developed over the past 15 years under European environmental regulation initiatives to minimize the level of global organic emissions (IEC 1999/13 CE). Much progress have been made. At the same time, efforts are ongoing to minimize VOC (volatile organic compound) resin content and to eliminate toxicological risks for workers and the environment. The range of solvent-free resins is growing quickly. For example, monomer-free resin solutions and resins containing reactive monomers/oligomers are green and safe and are not considered as volatile organic compound. However, due to their higher viscosity and slightly lower reactivity over solventless resins, they are generally less versatile and are best suited to well-optimized processes and impregnating equipment.

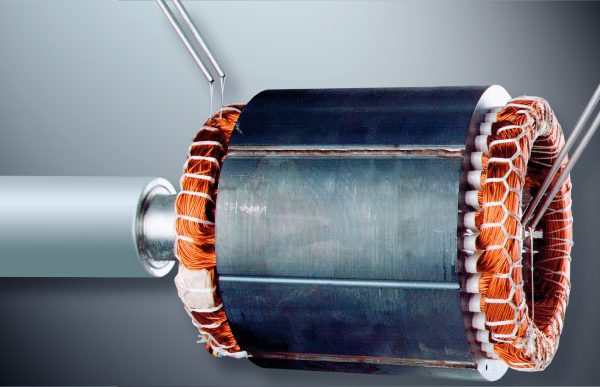

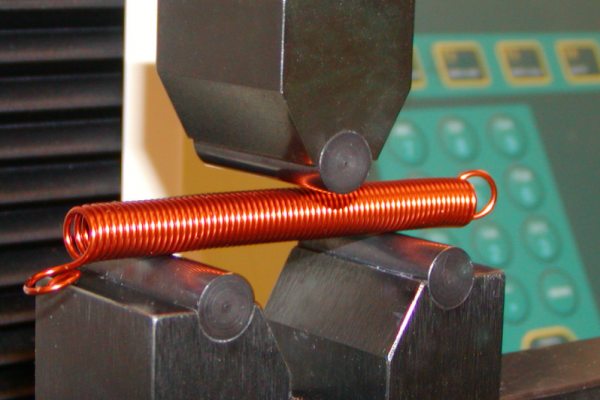

Dolph’s® varnishes and resins are integral components of insulating systems for all classes of rotating equipment, motors and generators. These materials provide environmental protection, vibration reduction and, in some cases, additional dielectric strength. The choice of the right material depends on the end-use application.

The product range of water-borne varnishes reflects the efforts of a dedicated team with worldwide experience, true concern for the environment, and substantial safety and technical expertise. A representative solution is our Aqua-Therm® product range, which includes the following attractive features:

Solventless resins are very reactive resins with monomers that could be considered to be VOCs. They show outstanding reactivity compared with varnishes and allow very quick penetration and draining due to their low viscosity. Nothing else at this stage can compete with these resins in term of high productivity and minimum process cost. Organic emissions can be substantially minimized through process choice.

Solvent-based varnishes are becoming increasingly less popular due to the effects of their solvent content and organic emissions. Nevertheless, due to their excellent tank stability, their versatile processability and typically good technical performance, they will continue to be important in the future.

Welcome to Europe’s leading center of expertise for high-voltage insulation for rotating machinery. Our knowledge of electrical insulation is based on over 100 years of experience. Discover more about us: